Servicing & Repairs

Service Republic specialise in keeping your coffee machines running at peak performance. As experts in coffee machine service and repair, we understand how crucial reliable equipment is for your business. Whether it’s routine maintenance or emergency repairs, our team of skilled engineers are here to ensure your machines operate smoothly, minimizing downtime and maximizing the quality of every cup.

Service Republic specialise in keeping your coffee machines running at peak performance. As experts in coffee machine service and repair, we understand how crucial reliable equipment is for your business. Whether it’s routine maintenance or emergency repairs, our team of skilled engineers are here to ensure your machines operate smoothly, minimizing downtime and maximizing the quality of every brew. With fast response times, expert diagnostics, and a commitment to customer satisfaction, we help you keep serving exceptional coffee, day in and day out.

Coffee equipment failure can happen at unexpected times, but don't worry we are always here to help. We service and repair all makes and models of commercial espresso machines.

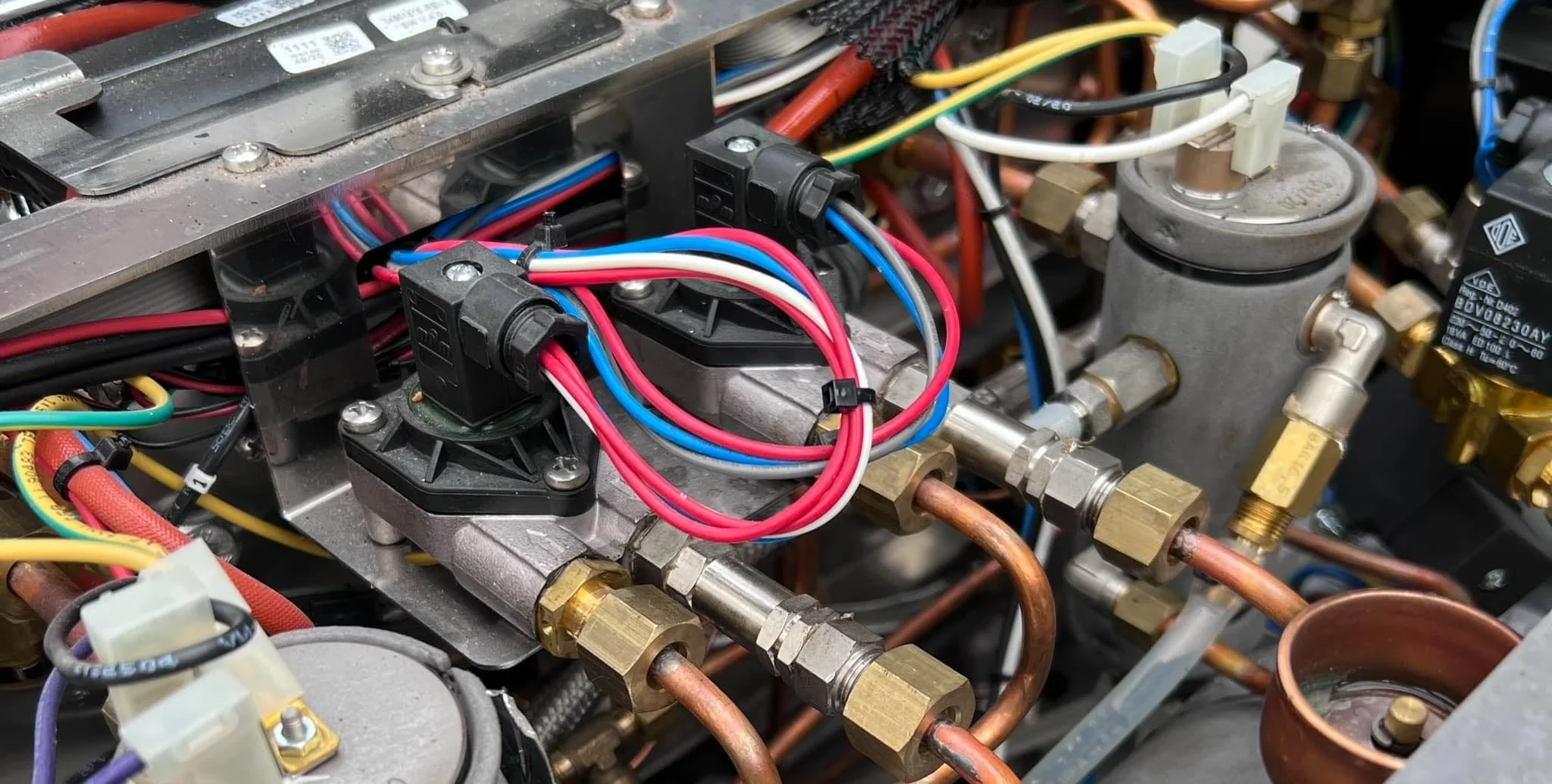

Our engineers repair and service all makes and models of commercial coffee machines and have over 20 years experience in this field. With over 30 different manufacturers of traditional type commercial espresso machines on the market from all corners of the globe, they are generally all built with the same universal components.

The only parts inside an espresso machine that are unique to each individual manufacturer is the steam tank, pipework, wiring and PCB, which in fairness don't cause faults very often. It's usually a flowmeter, solenoid valve or pump head which causes the most machine faults along with not being serviced regularly.

For this reason our engineers carry a large varied stock of universal components which are interchangeable to nearly all commercial traditional espresso machines to get you back making coffee in the least downtime possible.

If for any reason we do not have the part we can source and supply the part on a next day delivery direct to site from UK based suppliers.

Preventative Maintenance & PSSR Safety Inspections

6 Monthly Front End Service

-

• Replace group seals & shower plate/baskets

• Clean group injectors if required

• Calibrate pump pressure to 9 bar

• Calibrate steam pressure to machine specification

• Calibrate expansion valve

• Calibrate pressure switch (mechanical type only)

• Visual inspection for leaks

• Confirm correct operation of all machine components

• Calibrate grinder to include coarseness and dose weight

• Calibrate all shot selections on espresso machine

• Report any advisories

Annual Service

-

• Replace group seals & shower plate/baskets

• Replace steam valve seals

• Replace group solenoid valve seals

• Replace expansion valve seal

• Replace anti-vacuum valve

• Replace steam tank safety valve

• Replace porto-filter inserts & spring clips

• Clean group injectors if required

• Clean level probe

• Calibrate pump pressure to 9 bar

• Calibrate steam pressure to machine specification

• Calibrate expansion valve

• Visual inspection for leaks

• Confirm correct operation of all machine components

• Remove & clean waste hose

• Replace water filter

• Calibrate grinder to include coarseness and dose weight

• Calibrate all shot selections on espresso machine

• Report any advisories

PSSR Safety Inspection

-

A Pressure System Safety Regulation (PSSR) inspection is a legal requirement in many countries for businesses that operate pressure systems, such as commercial coffee machines, boilers, and air compressors. It ensures that the equipment is safe to use, properly maintained, and does not pose a risk to people or property. The inspection is part of the broader regulatory framework designed to prevent accidents due to pressure system failures.

Key Elements of a PSSR Inspection:

1. Compliance with Legal Standards:

• The Pressure Systems Safety Regulations (PSSR) require businesses to follow specific guidelines for maintaining and inspecting equipment that operates under pressure. This ensures that the system meets safety standards to prevent explosions, leaks, or failures.

2. Thorough Equipment Assessment:

• The inspection involves a detailed examination of the pressure system, including the boilers, pipes, valves, and safety devices. Inspectors check for signs of wear, corrosion, or damage, as well as the integrity of seals and gaskets that maintain system pressure.

3. Testing of Safety Devices:

• Pressure relief valves, safety interlocks, and other critical safety devices are tested to ensure they function properly in the event of an overpressure situation.

4. Risk Assessment and Preventive Maintenance:

• Inspectors assess the risk of failure by examining the operating conditions and historical performance of the system. They may recommend preventive maintenance or part replacements to avoid future issues.

5. Record Keeping and Certification:

• After a successful inspection, the system owner is provided with a written report or certificate detailing the results and any required actions. Businesses must keep these records and ensure they are available for future reference or regulatory audits.

6. Periodic Inspections:

• Depending on the type of equipment and operating conditions, inspections are required at regular intervals. The frequency is usually defined by a Written Scheme of Examination (WSE), which is a document outlining how and when the system should be examined.

Why PSSR Inspections Are Important:

• Safety: Ensures the safety of employees, customers, and property by preventing accidents caused by pressure system failures.

• Legal Compliance: Avoids legal penalties or shutdowns by ensuring compliance with health and safety regulations.

• Operational Efficiency: Helps maintain system efficiency and prevent costly breakdowns or downtime.

• Liability Protection: Reduces the risk of legal action in the event of an accident by demonstrating that the system has been properly inspected and maintained.

In summary, a PSSR inspection is a crucial process that helps businesses maintain safe and reliable operation of their pressure systems, while ensuring compliance with safety regulations.

Grinder Servicing & Water Treatment

Grinder Burr Replacement

-

Dependant on the make and model of grinder the blades can become worn anywhere between 250kg or upto 1000kg

Replacing the blades of your coffee bean grinder is essential for several reasons:

1. Consistent Grind Quality

• Sharp blades ensure a uniform grind size, which is crucial for brewing consistency. Dull blades can lead to uneven grounds, affecting extraction and resulting in a weaker or overly bitter cup of coffee.

2. Optimal Flavor Extraction

• Coffee flavor depends heavily on how evenly the beans are ground. Worn blades create uneven particles, with some being too fine and others too coarse, leading to poor extraction and a less flavorful brew.

3. Improved Efficiency

• Sharp blades grind beans more quickly and efficiently. As blades dull, the grinder has to work harder, which can strain the motor and lead to overheating or even damage over time.

4. Consistency Across Batches

• In commercial settings, where coffee quality needs to be consistent for every customer, regularly replacing grinder blades ensures that each cup meets the same standard, maintaining customer satisfaction.

5. Preventing Heat Buildup

• Dull blades generate more friction, which can cause heat buildup during grinding. This heat can scorch the coffee grounds, altering their flavor and reducing the overall quality of the coffee.

6. Prolonged Grinder Life

• Regularly replacing the blades helps maintain the overall health of the grinder. Struggling with dull blades puts extra strain on the motor and other components, potentially leading to costly repairs or even premature failure of the grinder.

In short, replacing your grinder blades keeps your coffee tasting fresh, ensures efficiency, and prolongs the life of your equipment, making it essential for both quality and cost-effectiveness.

Grinder & Machine Calibration

-

Calibrating your grinder and espresso machine is essential for maintaining consistent coffee quality and machine performance. Here are the key benefits:

1. Optimal Coffee Flavor

• Proper calibration ensures that the grind size and brewing parameters (temperature, pressure, extraction time) are perfectly matched, resulting in the best possible flavor from your coffee beans. This helps to avoid under-extraction (sourness) or over-extraction (bitterness).

2. Consistency in Every Cup

• Calibration guarantees that every cup of espresso is brewed with the same precision, ensuring consistent quality for every customer or user. Consistency is crucial, especially in commercial environments, to meet customer expectations.

3. Improved Extraction Efficiency

• Calibrating the grinder and espresso machine ensures the right ratio of coffee grounds to water, allowing for efficient extraction of flavors and oils from the coffee. This maximizes the potential of the beans and ensures no flavor is wasted.

4. Reduction in Coffee Waste

• When your grinder and espresso machine are calibrated correctly, you avoid wasting coffee due to incorrect grind sizes or faulty machine settings. This helps save costs, as each shot uses the right amount of beans with minimal waste.

5. Prolonged Equipment Lifespan

• Proper calibration helps prevent unnecessary strain on the grinder or espresso machine. By optimizing their performance, you reduce wear and tear, which can extend the lifespan of both the grinder and espresso machine.

6. Better Control Over Variables

• Calibration gives you precise control over key variables like grind size, water temperature, and pressure. This is especially important in professional settings where baristas need to make slight adjustments based on different types of coffee beans or brewing conditions.

7. Increased Customer Satisfaction

• A well-calibrated system ensures that every espresso shot meets the highest standard of quality, which directly impacts customer satisfaction in cafes or restaurants. High-quality espresso leads to repeat business and positive reviews.

8. Enhanced Efficiency and Workflow

• With proper calibration, your machines work more efficiently, reducing downtime caused by improper extraction or grind issues. This smoothens the workflow for baristas and speeds up service in busy environments.

In summary, calibration improves flavor consistency, reduces waste, extends equipment life, and enhances the overall coffee experience, making it vital for both home baristas and commercial coffee businesses.

Water Treatment

-

Fitting a water filter on a commercial coffee machine is crucial for maintaining machine performance, coffee quality, and long-term cost savings. Here are the key reasons:

1. Improved Coffee Taste

• Water makes up about 98% of a cup of coffee, so its quality directly impacts the taste. A water filter removes impurities like chlorine, heavy metals, and odors that can alter the flavor, ensuring a cleaner, better-tasting cup of coffee.

2. Prevention of Scale Build-Up

• Hard water contains minerals like calcium and magnesium that cause scale (mineral deposits) to build up inside the machine. This can clog components, reduce water flow, and damage the heating element. A filter reduces mineral content, preventing scale buildup and ensuring smoother operation.

3. Extended Equipment Lifespan

• By reducing scale and mineral deposits, a water filter helps protect vital components of the coffee machine, such as boilers, pumps, and pipes, from wear and tear. This prolongs the life of the equipment and reduces the need for expensive repairs or replacements.

4. Lower Maintenance Costs

• Regularly using a water filter decreases the frequency of descaling and machine servicing. This minimizes maintenance costs and reduces downtime, keeping your machine operating efficiently and saving your business time and money.

5. Consistent Performance

• A water filter helps maintain consistent water quality, ensuring that your coffee machine can consistently brew at the optimal temperature and pressure. This leads to consistent coffee quality, which is especially important in a commercial setting where customer expectations are high.

6. Compliance with Manufacturer Warranties

• Many coffee machine manufacturers require the use of water filters to validate warranties. Failing to use a water filter or allowing scale to build up can void the warranty, leaving you responsible for repair costs.

7. Energy Efficiency

• Scale buildup inside the heating element forces the machine to use more energy to reach the desired temperature. A water filter helps maintain energy efficiency, leading to lower electricity bills and reduced environmental impact.

8. Reduced Downtime

• By keeping your machine free of scale and other contaminants, a water filter reduces the likelihood of breakdowns, keeping your coffee service running smoothly, especially during busy periods.

In summary, using a water filter enhances coffee taste, extends machine lifespan, reduces maintenance costs, and ensures consistent, efficient performance, making it essential for commercial coffee machines.